Premium Window Tinting Services in Milford, CT

Window tinting offers a range of benefits that enhance your vehicle's look and functionality. At The Detail Shop, we provide expert tinting packages that not only improve your car's style but also protect and cool its interior.

Window TinT

The Best in Automotive Window Tinting is Available

You cannot get better protection and style than with window tinting from The Detail Shop. Installing window tint film packages for drivers in Milford, Connecticut, our window tinting services transform the look and feel of any vehicle make or model. This is accomplished while offering powerful functional benefits as well.

Window tinting is:

- Designed to improve infrared heat rejection

- Helpful in blocking harmful UV rays

- Great at minimizing glare from sunlight or headlights

- Deters potential break-ins by keeping the interior of your vehicle out of sigh

Which tint % works best for you?

Choose your TiNT % ↓

The Detail Shop Pricing

Window Tint OPTIONS

Good Choice

standard Carbon Window Tint Film

Our Standard Carbon Window Tint not only blocks UV rays, infrared heat, and harsh glare but also enhances privacy, making your vehicle safer and more comfortable. Its durable, fade-resistant design ensures long-lasting performance, while improved energy efficiency helps regulate cabin temperature to reduce strain on your air conditioning.

Ultimate Choice

Ultimate Ceramic Window Tint Film

Experience unmatched comfort and protection with our Ultimate Ceramic Window Tint Film. Designed with advanced heat rejection, it keeps your car cooler, reduces air conditioning strain, and lowers energy use. Featuring a 2mil thick anti-scratch film, this tint offers exceptional durability while blocking harmful UV rays to protect your skin and interior. It also minimizes glare for safer driving and delivers enhanced clarity with a sleek, refined finish, the perfect blend of style and performance.

Better Choice

PREMIUM Ceramic Window Tint Film

Experience exceptional comfort and protection with our Premium Ceramic Window Tint Film. Designed for effective heat rejection, it helps keep your car cooler, reduces strain on your air conditioning, and lowers energy consumption. This advanced tint blocks harmful UV rays to protect your skin and interior, while reducing glare for safer driving. With improved clarity, reliable durability, and a sleek, polished look, it’s a great balance of style and performance.

The Detail Shop Pricing

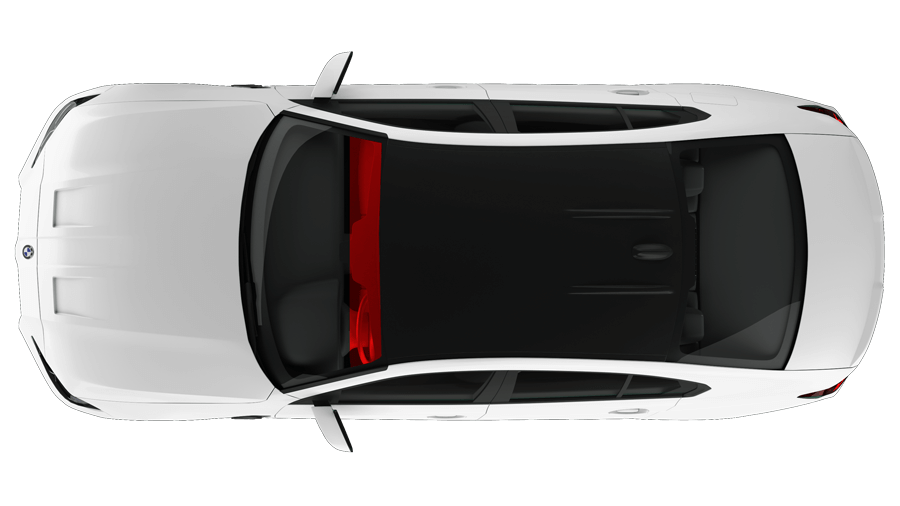

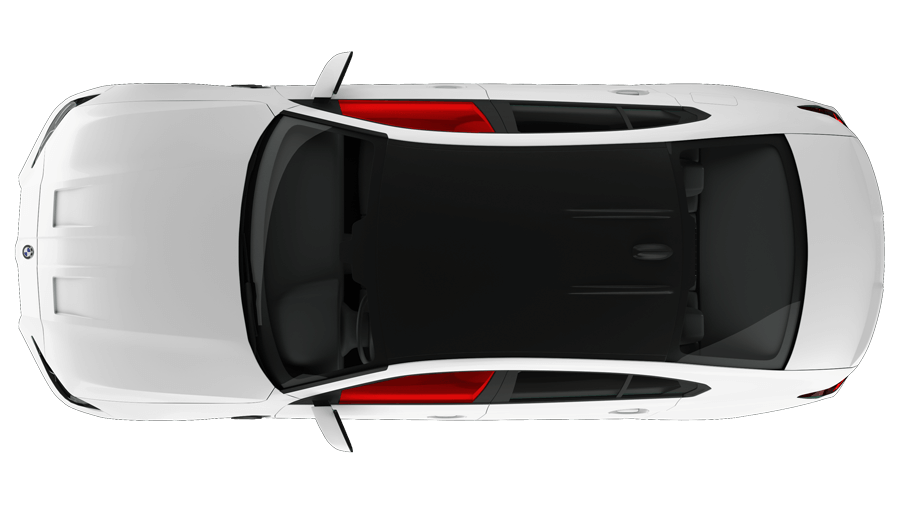

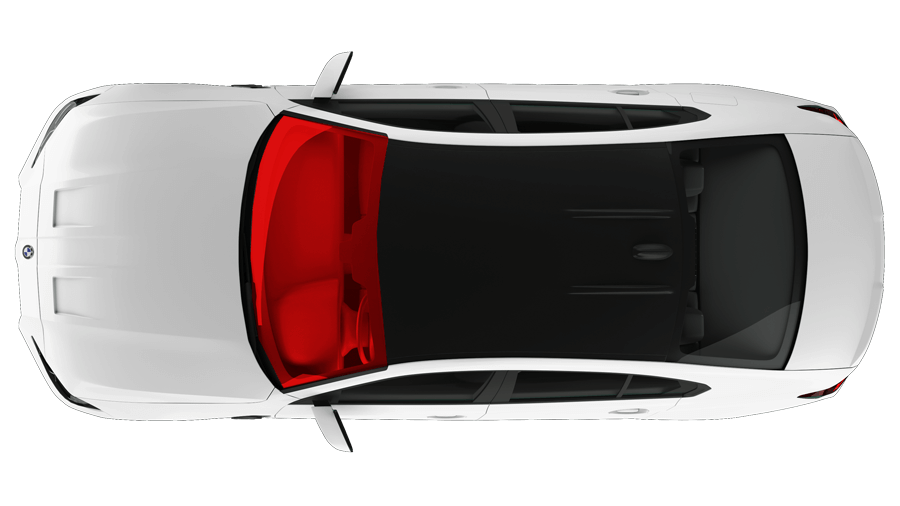

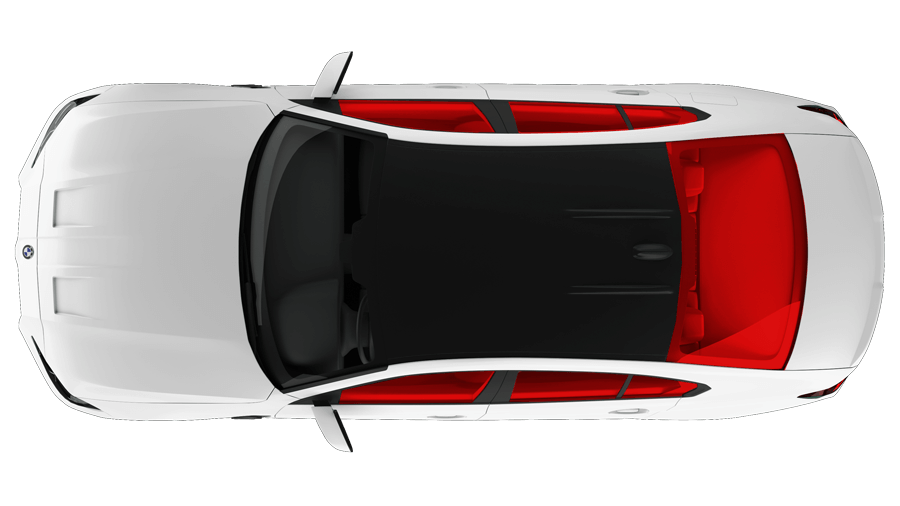

Our Coverage Options

Window Strip

- Cuts glare without hindering your view

- Assists in shielding your your eyes from harsh sunlight

- Adds a sleek, stylish finish

Price: $69 for All Tint Types

Front Two Windows

- Keeps interiors cooler by blocking heat

- Protects skin and upholstery from UV rays

- Enhances privacy with a polished look

Price starts at $159

Full Windshield

- Blocks harmful UV rays for full protection

- Reduces glare for safer driving

- Improves interior temperature control

Price starts at $179

All Sides and Rear Window

- Rejects heat for a cooler ride

- Shields from UV damage inside and out

- Ensures a refined, uniform look

Price starts at $395

Tint Removal

Starting at $35 Per Window

The Detail Shop is proud to offer professional tint removal services to help you refresh your vehicle’s look. Our skilled team ensures a quick and efficient process, removing old or damaged tint cleanly without harming your windows. Whether you’re upgrading to a new tint or restoring the original glass, we’ve got you covered

Customized Window Tint

Providing Precision Tinting Installation

A sleek window tint package always adds a modern, sophisticated edge to your vehicle's overall appearance. Getting your windows tinted at The Detail Shop is a meticulous process. You get a flawless finish no matter your selected coverage option. Each window tint is custom-fit to match your vehicle’s exact glass dimensions. Our expert technicians are well-versed in the window tinting brands we install. We apply the window tint film directly to the glass surfaces, allowing it to cure for a lasting bond you can rely on. The result is a seamless integration that does not peel, bubble, or fade.

Experience Our Meticulous Process

Tint Your Windows with The Detail Shop

No matter what make or model vehicle you drive, window tinting is a valuable upgrade that benefits all types of vehicle owners and driving lifestyles! From daily commuters to the discerning auto enthusiast, The Detail Shop is Milford, Connecticut’s premier provider of professional window tinting. Our packages add tremendous value, style, and protection to your ride. We are ready to set a new standard for vehicle comfort, style, and protection all around

CALL (203) 816-5006

We Offer Top Window

Tinting Packages

Learn More About Window Tint

Myths About Window Tinting-Solved

Myth 1: Window tinting makes it hard to see while driving at night

This is not true. When the proper level of window tinting is chosen, you will not have a problem seeing during darker driving hours. High-quality window tinting is designed to reduce glare without drastically reducing visibility. We have varying levels of tint darkness at The Detail Shop, all of which are engineered to maintain clear vision at night.

Myth 2: Window tinting is only for improving vehicle looks

While it certainly enhances a vehicle's visual appeal, window tinting provides much more than a sleek look. It blocks UV rays, reduces interior heat buildup, and adds a layer of privacy to your vehicle’s interior. All of these functional benefits significantly improve comfort and protect both passengers and the vehicle interior.

Myth 3: Window tintingis technically an illegal upgrade in Connecticut

This is an unfortunate wide spread myth about window tinting. To be clear, window tinting is legal in all 50 states. However, each state has its own specific laws regulating how dark window tinting can be and on what size vehicle. Likewise, there are rules about where it can be applied to your vehicle. These regulations are in place to ensure safety and visibility for both drivers and law enforcement officials. When installed within legal limits, window tinting is completely compliant and provides a range of benefits without violating any laws.

Myth 4: The darker the tint, the better the heat rejection

Window tinting is not just about darkness. It is about the quality and technology of the window tinting material. Some of the most advanced window tinting packages are less dark in shade than others while still offering exceptional infrared heat and UV ray rejection .For example, lighter shades of ceramic and nano-ceramic tinting options often outperform dark, outdated window tinting options

Advantages

Understanding All the Benefits of Window Tinting

Superior Heat Reduction for a Comfortable Ride

Window tinting from The Detail Shop helps block infrared rays, significantly reducing the internal temperature of your vehicle. This results in a cooler and more comfortable environment for you and your passengers, especially during hot summer months in Connecticut. It also lessens your reliance on air conditioning, which can extend the longevity of those components. You get to enjoy a pleasant driving experience even in extreme heat conditions.

Protection Against Harmful UV Rays

Window tinting is an invisible safeguard for everyone inside your vehicle. High-performance window tinting from The Detail Shop blocks up to 99% of harmful UV rays from the sun. This protection level helps preserve your vehicle’s interior, preventing fading of upholstery, dashboards, and other surfaces. More importantly, it reduces UV exposure for passengers, minimizing the risk of skin damage during long drives

Enhanced Driver and Passenger Privacy

Window tinting adds a level of privacy to every drive. By limiting outside visibility into your vehicle, the window tinting packages we have keep your interior a secret. It also cuts down on glare from the sun and oncoming headlights at night, improving driver visibility and reducing eye strain. Whether you are on a busy highway or parked on a city street, window tinting gives you peace of mind and a much clearer view overall

Save Energy, Reduce Glare, & Increase Privacy

Fill out and submit our quote form & our expert window tint installers will reach out ASAP with a direct quote.